Embed 3D artwork into your website

Your customers can interact with their favorite designs in real-time

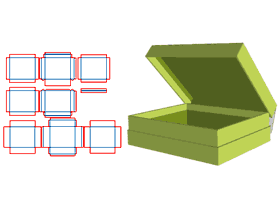

Strongest box template Library

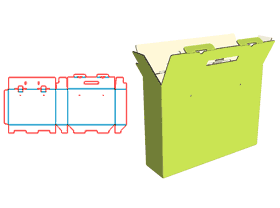

Card box, paper box, flip box, handbag, hardcover box, display rack

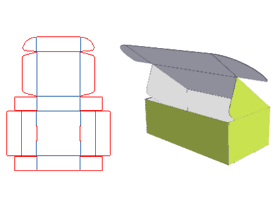

Add and update box templates

Opposite flip gift box, boutique box, handbox, cardboard box, gift box, hardcover box, tea box, moon

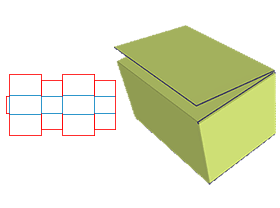

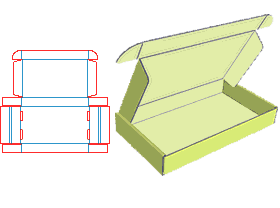

0203 box|international standard corrugated carton

Cartons are the most widely used packaging products, according to different materials, there are cor

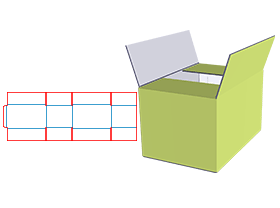

Packaging carton design, 0427 box type, keyboard packaging design, aircraft box, color box card tray

Packaging carton design, 0427 box type, keyboard packaging design, aircraft box, color box card tray

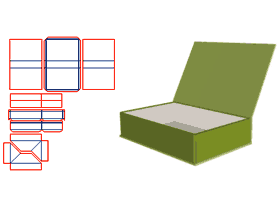

gift packaging box design|heath care product packaging/fruit packaging

Foldable, book-shaped boutique box, leather shell triple board, gray board semi-pierced X, book-shap

Foldable, book-shaped boutique box, leather shell five-plate, gray board semi-worn molding X, book-s

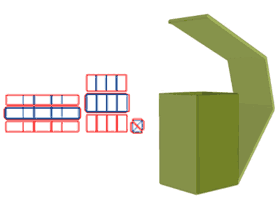

Intelligent structure design

Input length, width, height, paper thickness, system intelligent generation structure chart

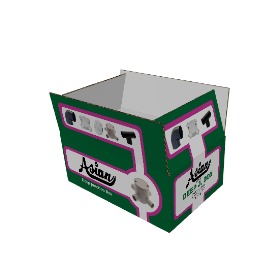

Generate 3D renderings in one minute

Paste the printing plan and generate 3D effect immediately

What we've shared